Modeling and Real-Time Control of Energy Storage Using HPCS Technologies

Modeling and Real-Time Control of Energy Storage Using HPCS Technologies

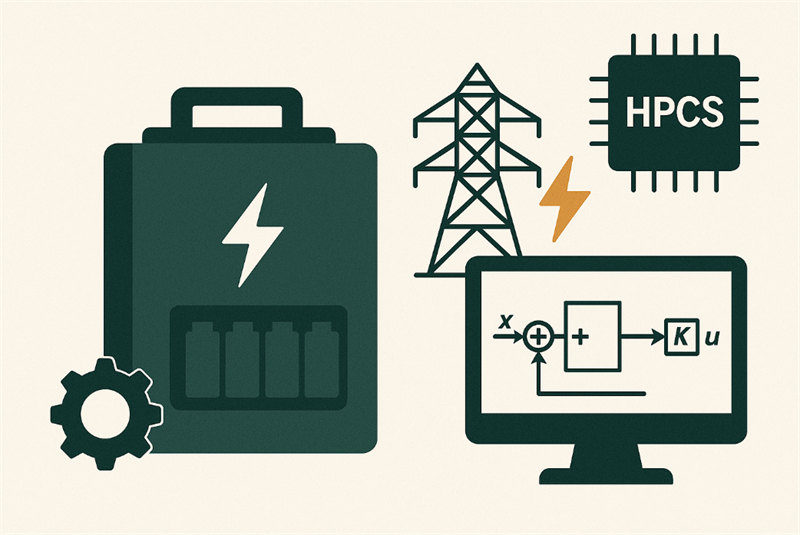

As the global transition toward renewable energy accelerates, energy storage systems (ESS) have become indispensable for maintaining grid stability, managing peak loads, and ensuring continuous power supply. However, the increasing complexity of integrating diverse power sources, variable loads, and bidirectional energy flows necessitates smarter control and management strategies. High-Performance Control Systems (HPCS) have emerged as a key enabling technology to meet these demands.

In this article, we explore how HPCS technologies enhance the modeling, simulation, and real-time control of modern energy storage systems, particularly in grid-connected and hybrid renewable applications.

The Role of HPCS in Energy Storage

High-Performance Control Systems are advanced computational platforms equipped with real-time operating systems, high-speed processors, and optimized control algorithms. These systems are designed to handle complex, high-frequency control tasks with deterministic timing—making them ideal for managing Battery Energy Storage Systems (BESS), flywheels, supercapacitors, and hybrid storage architectures.

Key Advantages of HPCS in ESS:

-

Real-Time Processing: Millisecond-level control response for voltage, current, and frequency regulation.

-

Scalability: Modular architectures support integration with microgrids, distributed energy resources (DERs), and large-scale utility storage.

-

Advanced Algorithm Deployment: Supports implementation of model predictive control (MPC), adaptive filtering, and AI-based optimization.

-

Data Acquisition and Analytics: High-throughput data logging for diagnostics, performance optimization, and predictive maintenance.

Modeling Energy Storage Systems for Control Optimization

Before deploying real-time control strategies, a detailed and accurate model of the energy storage system is essential. HPCS platforms allow for embedded modeling, enabling real-time simulation and Hardware-in-the-Loop (HIL) testing. This is critical for validating control logic under various operating conditions.

Key Modeling Components:

-

Electrical Model: Captures battery characteristics, equivalent circuit models (e.g., Thevenin or RC models), internal resistance, and state of charge (SoC).

-

Thermal Model: Simulates thermal dynamics to ensure temperature control and system longevity.

-

Degradation Model: Predicts aging and capacity fade, enabling lifecycle-aware control decisions.

-

Grid Interaction Model: Reflects grid voltage variations, frequency deviations, and power flow constraints.

These models can be continuously updated using real-time sensor data and adaptive estimation algorithms, ensuring that the control logic remains accurate over the lifetime of the system.

Real-Time Control Strategies Using HPCS

Once a robust model is in place, HPCS can execute sophisticated real-time control strategies to ensure optimal performance and safety.

Common Real-Time Control Functions:

-

SoC and SoH Management: Precise estimation and management of battery state of charge and health.

-

Charge/Discharge Optimization: Dynamic adjustment of power flows based on load demand, electricity pricing, and renewable generation forecasts.

-

Grid Services: Frequency regulation, voltage support, spinning reserve provisioning, and black start capability.

-

Fault Detection and Recovery: Real-time monitoring for overvoltage, overcurrent, thermal excursions, and cyber-physical threats.

These functions are implemented through a layered control architecture, typically including:

-

Primary Control: Fast response for voltage/current stabilization.

-

Secondary Control: Manages SoC balance and power sharing across multiple storage units.

-

Tertiary Control: Handles economic dispatch, scheduling, and communication with grid operators or energy markets.

Deployment and Integration Considerations

Deploying HPCS for energy storage control involves both hardware and software integration:

-

Hardware Selection: Real-time processors such as ARM Cortex-R, DSPs, or FPGA-based systems with dedicated ADC/DAC channels.

-

Communication Protocols: Support for Modbus, CAN, Ethernet/IP, and IEC 61850 for SCADA and grid integration.

-

Cybersecurity: Embedded security mechanisms including encryption, authentication, and intrusion detection.

Moreover, HPCS should comply with grid codes (e.g., IEEE 1547, ENTSO-E standards) and support remote firmware updates and diagnostics.

Conclusion

High-Performance Control Systems are transforming the landscape of energy storage technology. Through accurate modeling and real-time control, HPCS platforms enable safer, more efficient, and grid-responsive storage systems. As the demand for energy resilience and flexibility grows, investing in HPCS-based solutions is not just beneficial—it's essential. yy